L-R: Andrea, Jayden and Graeme Barlow (Yarram) with Daviesway's Brendan McGrath.

L-R: Andrea, Jayden and Graeme Barlow (Yarram) with Daviesway's Brendan McGrath.

CAN A ROTARY TRULY BE A “ONE-PERSON” DAIRY?

Clever management has allowed a Victorian family to help underwrite a second (and new) one-man rotary out of increased cashflow on their Victorian operation.

Andrea and Graeme Barlow – together with Andrea’s parents, Ken and Marina Dixon – operate a two-way partnership at Yarram, in southeast Gippsland. The property is managed by their son, Jayden, who is supported by his partner, Ekala. The family farms 1011 hectares [2500 acres], milking 1000 cows in two herds through two rotaries – sited 2.5km apart.

The Coles suppliers have a 65% spring to autumn-calving regime. The herd averages 8000 litres with a BMCC [Bulk Milk Cell Count] average of 90,000.

When this family committed to chasing down the one-man rotary ideal – using technology and automation – they had to first conquer some other challenges within their business.

CHANGE MUST COME

In 2007 the family had bought an adjoining 161ha [400 acres]. The property came with an aging 44-year-old 42-stand rotary. The bank immediately allocated funds for them to build a new dairy (No.2 dairy) on the farm.

Centre "donut" section prepared ready for concrete.

Centre "donut" section prepared ready for concrete.

Yarroweyah Engineering platform completed ready for the milking machine installation.

Yarroweyah Engineering platform completed ready for the milking machine installation.

Automation coupled with smart management has taken this dairy as close to a one-man rotary as possible.

Automation coupled with smart management has taken this dairy as close to a one-man rotary as possible.

Instead, the family continued to milk two herds through their home dairy and that aged rotary for the next 17 years.

Significantly in 2021, the business (which trades as D & B Farms Trust), won Gold in Dairy Australia Milk Quality Awards (top 100 herds). It won Silver in 2022, 2023, and 2024.

Combining a strong production average with a low BMCC within a big herd being milked through two dairies – while coping with the acquired dairy that had a lot of challenges – is a telling clue about this family’s commitment to performance and udder health.

Another time sinkhole for the business was irrigation. They were irrigating with 350 bike-shift laterals in the summer. And, they sustained three successive years of winter flooding (which left water sitting on one-third of the farm, necessitating re-sowing, and seriously impacting their effective hectares). The sound of rain on the roof still sometimes triggers Jayden.

DECISIONS, DECISIONS

When they first re-visited building the No.2 dairy, they hesitated.

“We were going to build three or four years ago, and the quote got to nearly $2 million dollars, and we thought it was a lot of money for no more grass and no more milk,” Graeme said.

“We made the decision instead to add three centre pivot irrigators to the three we already had, so we could grow more grass, and make more milk to help pay for the dairy.

A drone view of No 2 dairy, showing round yard to the right of the main dairy shed, the old dairy in the foreground and a new machinery and storage shed to the left of the new dairy.

A drone view of No 2 dairy, showing round yard to the right of the main dairy shed, the old dairy in the foreground and a new machinery and storage shed to the left of the new dairy.

“Changing the irrigation freed up more time than we realised. Those laterals used to put two hours onto our days, and they would take two people.

“Now, it probably takes 30 minutes, we lifted production by 25% because we’re growing better pastures, and we have better pasture renovation.”

The extra production and income were key, because when they circled back to the problematic rotary in 2023, they had generated the cashflow they needed to help upgrade the home dairy into a one-man shed in December 2022. They started the No.2 dairy build in August 2023 (commissioning it in March 2024).

THE ELEPHANT IN THE ROOM

By this time the steel platform on the old dairy was slippery and dangerous for the cows, many of the cows were too big for the bails, the platform drives repeatedly broke down in its final six months (17 of its 25 bearings had to be changed in the last three or four months), and a significant amount of steel had rusted through, and been repeatedly patched up.

Jayden, 29, said it was taking two people more than six hours to milk every day. He felt like he was putting bandaids on it every other day, as it limped towards an end-of-life non-resuscitation conversation.

The new dairy (No.2 dairy) has transformed milking for the Barlow family and their loyal team.

The new dairy (No.2 dairy) has transformed milking for the Barlow family and their loyal team.

“Before we decided to build the No.2 dairy, we did briefly consider building a single and centralised 70 to 80-unit rotary in the middle of the farm,” Jayden said. “But you would have needed two people cupping up, so it would have still been a two-man unit and you’re only milking 80 cows [a round]. Also, we would have lost valuable grazing area and increased the distance the cows would have had to walk.

“The infrastructure would have also involved new power, laneways, effluent – and it was going to be a lot of work to put everything in a different spot. We’ve already got the concrete at the home dairy, and if we went with two dairies, we are effectively 20 cows faster with the same labour units [100 cows through two 50-stand rotaries every 10 minutes]. Maybe you’ll use slightly more acids and detergents and you’re cooling two vats, but it’s a lot easier for this home dairy.”

MANAGEMENT AND AUTOMATION EQUALLY KEY

They approached Daviesway DASCO’s technical sales representative in Warragul, Greg Lechte, to build an automated 50-stand rotary on a greenfield site [right beside the old 42-bail rotary].

Daviesway's Greg Lechte has been a trusted contact for the Barlow family for years.

Daviesway's Greg Lechte has been a trusted contact for the Barlow family for years.

Daviesway had built the family’s home dairy in 2003 and upgraded it before the No.2 dairy build – adding automation with a full Daviesway plant. The family wanted to mirror those decisions in the new build to take advantage of the synergies between the two hubs, so that staff and cows could be easily interchanged.

“That way there is less confusion,” Jayden said. “And, we knew it all worked because we had the Milkrite clusters, the CR-1 cup removers and the Teatwand EXACT already installed in the home dairy.”

MIlkrite Impulse 300 claws with the Milkrite triangle mouthpiece vented liners inserted in the VariFlo No 4 rubber cup jetter ready for washing.

MIlkrite Impulse 300 claws with the Milkrite triangle mouthpiece vented liners inserted in the VariFlo No 4 rubber cup jetter ready for washing.

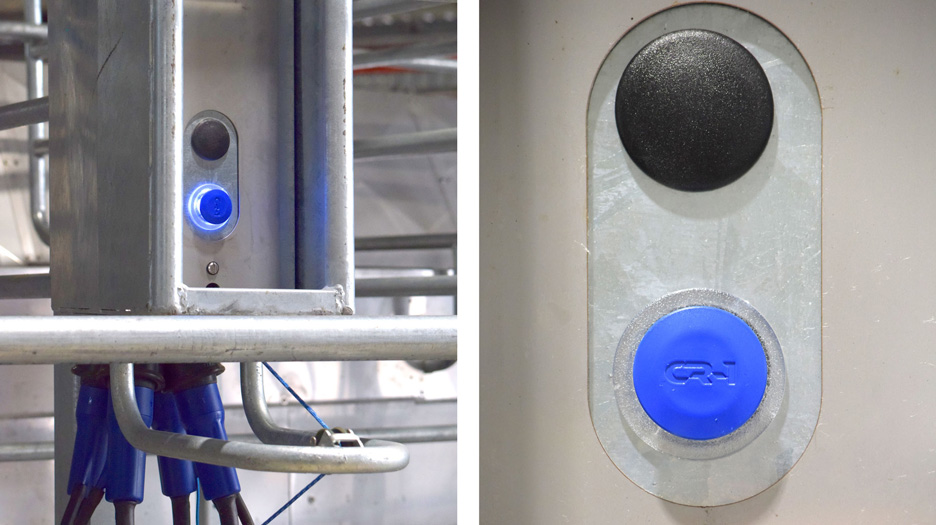

The CR-1 indicator switch mounted in the dummy bail. The bright LED shows status of the remover at all times, with the bright blue showing wash mode.

The CR-1 indicator switch mounted in the dummy bail. The bright LED shows status of the remover at all times, with the bright blue showing wash mode.

Cows are teat sprayed automatically by the Teat Wand Exact just prior to exit. The systems check for a cow, that a cluster is removed and the retention strap is raised to ensure only eligible cows are sprayed.

Cows are teat sprayed automatically by the Teat Wand Exact just prior to exit. The systems check for a cow, that a cluster is removed and the retention strap is raised to ensure only eligible cows are sprayed.

They also didn’t hesitate to include Daviesway’s project manager Nico Polato, who specialises in new builds on-farm – along with Rural Build’s Scott McCallion – for solid reasons. They knew there would be a lot of critical decisions in a new build, and they would only get one chance at it.

“Nico was brilliant. He knows what works and what doesn’t, and how to build a shed. He knows about the best cow flow, he’s done hundreds of them, and he’s been all over the world.

We knew exactly what he brought to the table, because we’ve been with Daviesway for years and we’ve worked with Nico before,” Jayden said.

Daviesway’s Project Manager Nico Polato was an invaluable resource for the Barlow family.

Daviesway’s Project Manager Nico Polato was an invaluable resource for the Barlow family.

There were some important points of difference in the way this build was handled that drove the final result.

The home dairy remains well established as the calving hub for the operation.

The No.2 dairy is reserved for the cows that are settled post-calving, and rolling comfortably towards peak production, or cruising in late production.

It was an important decision that means the No.2 dairy’s milkings are uncomplicated – allowing it to operate as a one-person rotary. Although help is always within easy reach. It takes 2.5 hours for one person to milk 400 cows (including getting the cows in and washing up).

“We have people floating around all the time. If we have something major at the No.2 dairy, like pregnancy testing, there is always someone who can go down and give a hand,” Jayden said.

“Honestly, we’ve made the No.2 dairy so simple that 95% of the time there is one person running the whole operation.”

SELECT CHOICES

The No.2 dairy features Daviesway’s select plant choices, including the CR-1 Automatic Cup Removers (ACRs) and Milkrite’s triangular milking science.

Its technology includes the cluster “lift to start” (which automatically switches to manual mode if they are held slightly longer), with rapid venting for softer pull-down, an adjustable retraction speed, a “max milking time” and being able to transfer all the milking points from milk-to-wash mode with a single switch.

Automation coupled with smart management has taken this dairy as close to a one-man rotary as possible.

Automation coupled with smart management has taken this dairy as close to a one-man rotary as possible.

They also included the cluster drop-down feature (so that the clusters automatically drop down and travel underneath the bridge without interfering with the cow’s entry or exit). The Daviesway pulsators have been one of Jayden’s high points, because they automatically cut out once the cluster comes off the cow, which stops any manure infiltrating the system.

“That’s a brilliant feature,” Jayden said.

They teamed the CR-1s and Milkrite clusters with rubber matting, a generous four-bale exit with a 2.5-cow-deep entry race to ease pressure and promote organisation at cups on. They invested in a Boumatic BP 400 vacuum pump system with variable speed drive, new industrial plate coolers, a Guardian II auto-wash system (customisable with five wash cycles), auto draft, a dedicated dairy office, toilet, milk room, and they have engineered easy access to the centre of the rotary where the power supplies are centrally located.

The heart of the plant wash system. The 650 litre temperature rated wash barrel on the right, Twin hot water services with a pump to ensure even pressure to the wash system. Then two stainless steel heat recovery systems on the right.

The heart of the plant wash system. The 650 litre temperature rated wash barrel on the right, Twin hot water services with a pump to ensure even pressure to the wash system. Then two stainless steel heat recovery systems on the right.

The "centre" of the dairy - the Daviesway gland that handles vacuum, milk delivery and all electrical power and signals.

The "centre" of the dairy - the Daviesway gland that handles vacuum, milk delivery and all electrical power and signals.

DAY-TO-DAY EASIER

Jayden says while the milking time at the No.2 dairy is similar, the differences within that are worth having.

Jayden Barlow said it made sense to build a second dairy, rather than centralising a single build in the centre of the property.

Jayden Barlow said it made sense to build a second dairy, rather than centralising a single build in the centre of the property.

“The new dairy has saved us one full labour unit, and Mum is milking a quarter of as many milkings as she used to. The milking time is more or less the same, but the milker gets the cows in themselves, instead of needing another person to get the cows in. The wash down is way better, and the backing gate has a washing system on it, so the yard is washed by the end of the milking.”

Andrea adds, “It’s as close to a one-man dairy as you can get. I enjoy milking in there. It’s quiet, comfortable and you no sooner start, and you’re finished. You get yourself into a routine, and it’s just an easy shed to work in.”

Graeme says they would make the same choices, given their time again.

“We didn’t do absolutely everything Nico wanted, but he allowed us to keep farming instead of building a rotary. He was the project manager; he kept everyone organised and flowing.

“I know it cost us, but we probably made more money farming than we did buggerising around trying to save money building a dairy.”

MANAGEMENT KEY TO ULTIMATE SUCCESS

Daviesway’s Nico gives most of the kudos to this family’s management.

“It’s not like this dairy has more automation than others – we are serving these features up fairly regularly these days – but it’s the whole system and the management of that automation by this family that really wraps it up into a significant ball,” Nico said.

“One of the things I remember was watching Andrea on the first milking and just how patient and good she was with the cows.

Cows are calmly standing with a hoof wither side of the leg spreader - allowing easy access to the udder for milking and spraying. It is easy to see the Green status on the CR-1 switch.

Cows are calmly standing with a hoof wither side of the leg spreader - allowing easy access to the udder for milking and spraying. It is easy to see the Green status on the CR-1 switch.

“One of the things we consistently talk about, is that we are building a cool, calm facility for the operators’ and the cows’ welfare and comfort. Everyone should enjoy milking time. It’s a joy to see when it all comes together.”

If a cow deviates from either her expected milking or health perimeters she is retained and sent back to the cups-on operator with an alert – or she will be drafted into one of the sort pens. The dairy shed generates its own herd test once a month. The parlour entry identification and computer-generated feed rations for each cow is another automated efficiency. There is also back-up for treated or fresh cows.

“If the operator misses the flag, a voice activated message or a screen at cups-on will show a red line through that cow,” Nico said.

“If they miss that, the system can block the operator from activating that unit.

The level of automation we’ve got there and the communication between the milking and identification equipment is exceptional.

“We can now evaluate a lot of things about each cow before she gets off the deck regarding her production, reproduction, and general health,”

Nico said.

“It has certainly been a real pleasure to watch this family’s success and progression over many years, and to be asked to come back to the table for this build 20 years later.”

STAFF AND EXPECTATION

Left - Teatwand EXACT Automated teat spray in action. Right - Eric Perlado is the production manager at the No.2 dairy.

Left - Teatwand EXACT Automated teat spray in action. Right - Eric Perlado is the production manager at the No.2 dairy.

They now employ six fulltime staff, including Eric Perlado, who is the production manager at the No.2 dairy. Eric moves easily between the two farms and is enjoying the easier running with the new dairy and automated irrigation. Graeme and Andrea’s nephew, Nicolas Hill, who has also been with the family for two years through a TAFE traineeship. Graeme added, “We’ve always had really good staff retention, but the changes have definitely helped. One staff member has been here nearly 20 years. We’ve had the same team – bar one milker (who keeps having children and thankfully coming back) and Eric – for the last four years.

“We do get offered back packers, but to be honest I couldn’t think of anything worse than training someone, watching them getting it right, losing them, and then doing it all over again. It’s like a never-ending story.”

SUMMARY

Changing the dairy and irrigation has been the right move at the right time.

“Before we were working our guts out and things weren’t getting done properly. Now things are getting done properly, and it’s showing in the vat,” Jayden said. “We’ve got time to make decisions instead of making those calls on the run and half doing things.”

Graeme adds, “With the centre pivot irrigation, we can grow a lot more grass than we could have, and it takes a lot less time to do it. We don’t wear a motorbike out every year, and we go through a quarter of the fuel we used to use shifting those laterals.”

Jayden finishes, “The dairy had to be done, and collectively both of these moves have absolutely made us all feel better.

“Daviesway were brilliant to deal with. Everything they said was going to happen, happened.”

Rubber matting has been installed in the exit area to reduce the amount of wear on cow's hooves when they back off and turn to leave the rotary.

Rubber matting has been installed in the exit area to reduce the amount of wear on cow's hooves when they back off and turn to leave the rotary.

“The liner is the most important thing in the dairy – next to the cow and operator,” Nico said. “All the rest of the equipment is simply milk-path transport equipment. “We’ve seen the net results of this technology on so many farms in Australia, and around the world, and they speak for themselves. The improved teat condition, lowered SCC [somatic cell count] results, calm cows, less cup slippages … and the list goes on.”

NICO POLATO

DAVIESWAY SPECIAL DAIRY PROJECT MANAGER

Mobile: 0428 517 363

Email:

FREE CALL DAVIESWAY – 1800 600 269

See more Daviesway Dairy project information below

![]() Daviesway – Build Your Dairy Your Way

Daviesway – Build Your Dairy Your Way![]() Milkrite Triangular Vented Liners – Why are they so good?

Milkrite Triangular Vented Liners – Why are they so good?

![]() Dairy needs updating – Renovate or build?

Dairy needs updating – Renovate or build?

.